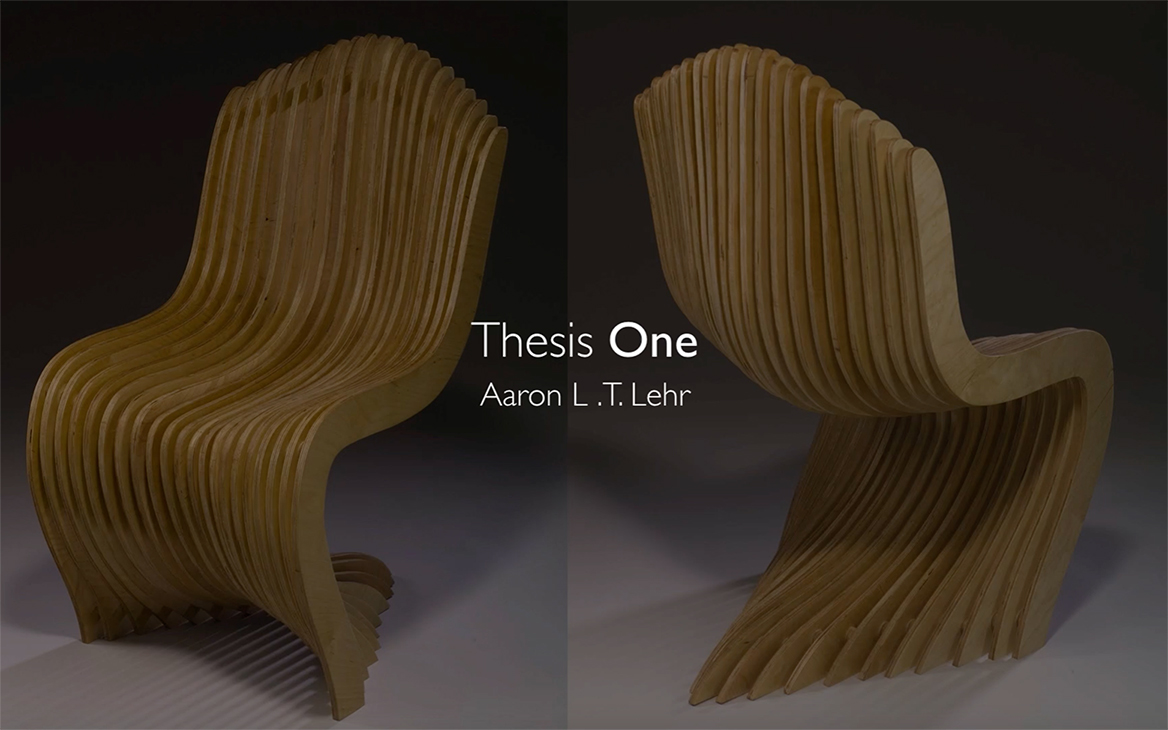

Introduction

Align is system of custom chair design and manufacture that uses digital scanning and fabrication to create a chair designed precisely for each individual. My goal is to improve the design of furniture and its relationship to the human body by integrating additive manufacturing, 3D scanning and generative modeling as production methods. This process will customize the manufacturing of chairs to individual sitters. My research began with the history of chair design and manufacturing in order to understand why chairs are designed for an “ideal” person. Today the majority of our time is spent sitting rather than active, due to a shift away from manufacturing jobs, and we are now noticing the negative effects on our bodies. Trends like the standing desk, ball chairs and stools have been the only solutions offered.

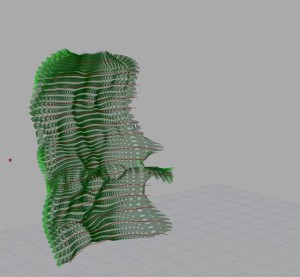

To offer a better option I am creating a system to produce a custom, form-fitting 3D printed foam mesh structure that can then be applied to a mass produced framework chair in forms such as a desk, lounge, dining chair or even a car seat. I designed and developed a flexible 3D printable foam structure that can be formed to a person’s body. The structure allows any part of the chair to be customized for shape, density and softness which can be used to affect the way a person sits in a chair, potentially improving posture and ergonomics. Finally I plan to apply studies of medical ergonomics, orthopedics and pain mediation to create custom chairs that will improve one’s posture and comfort.

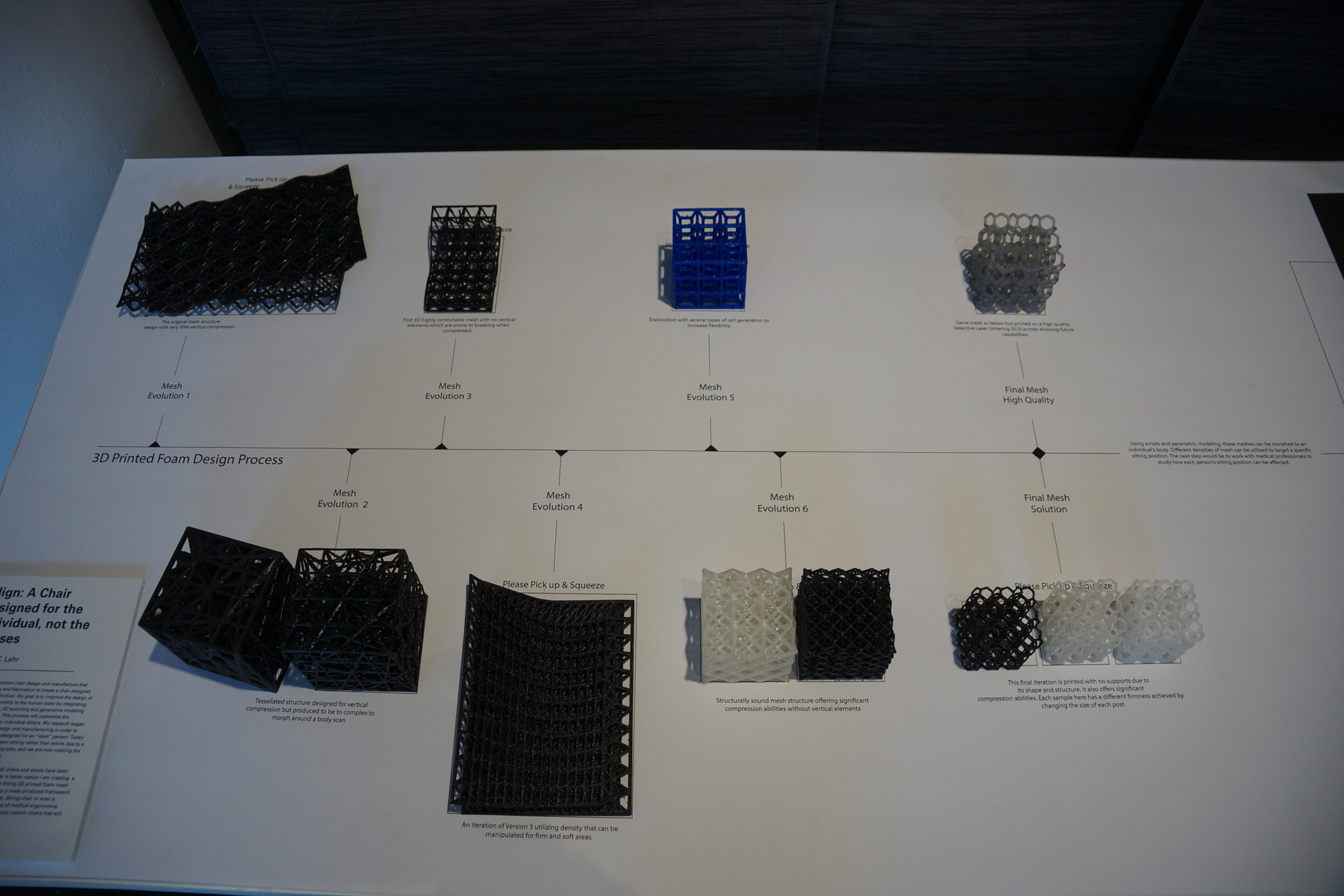

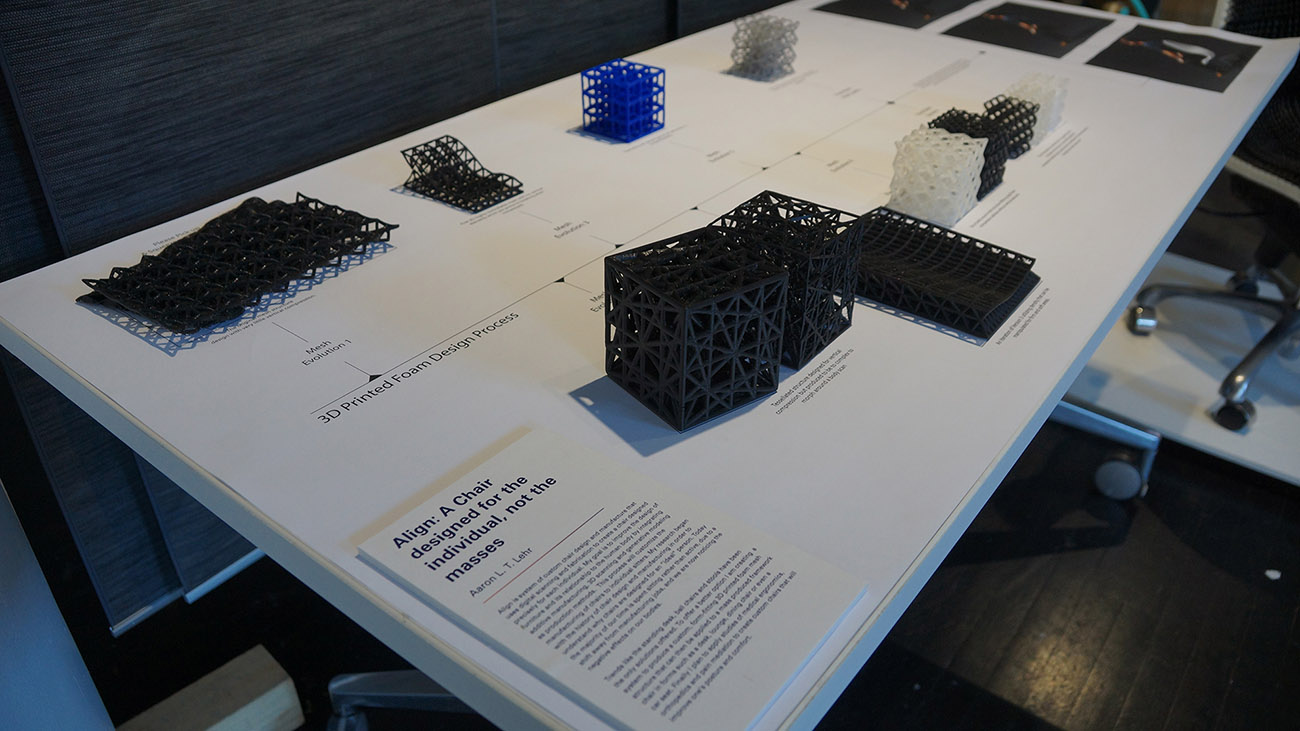

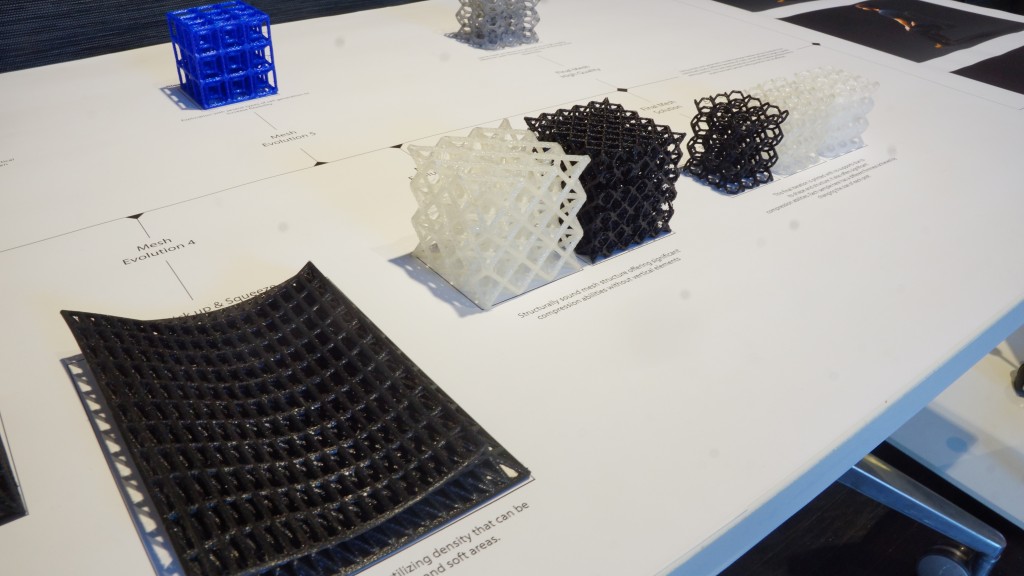

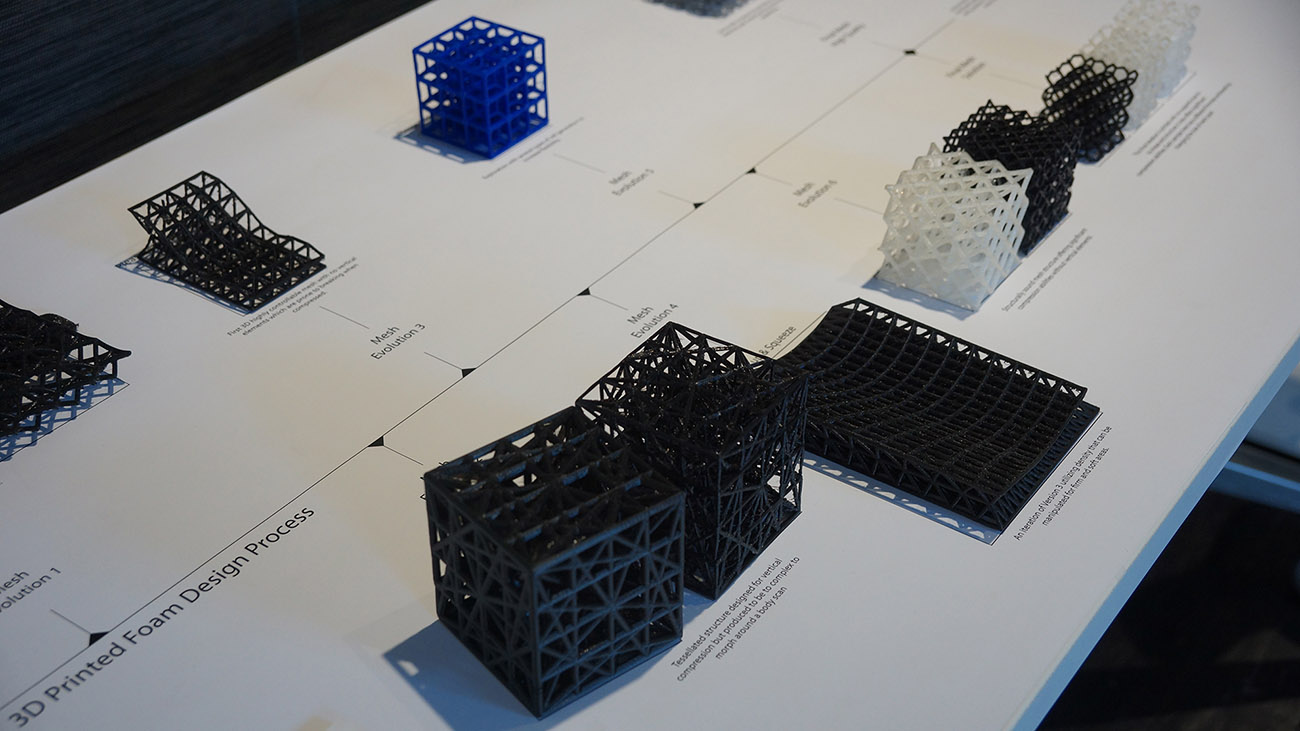

Manufacturing

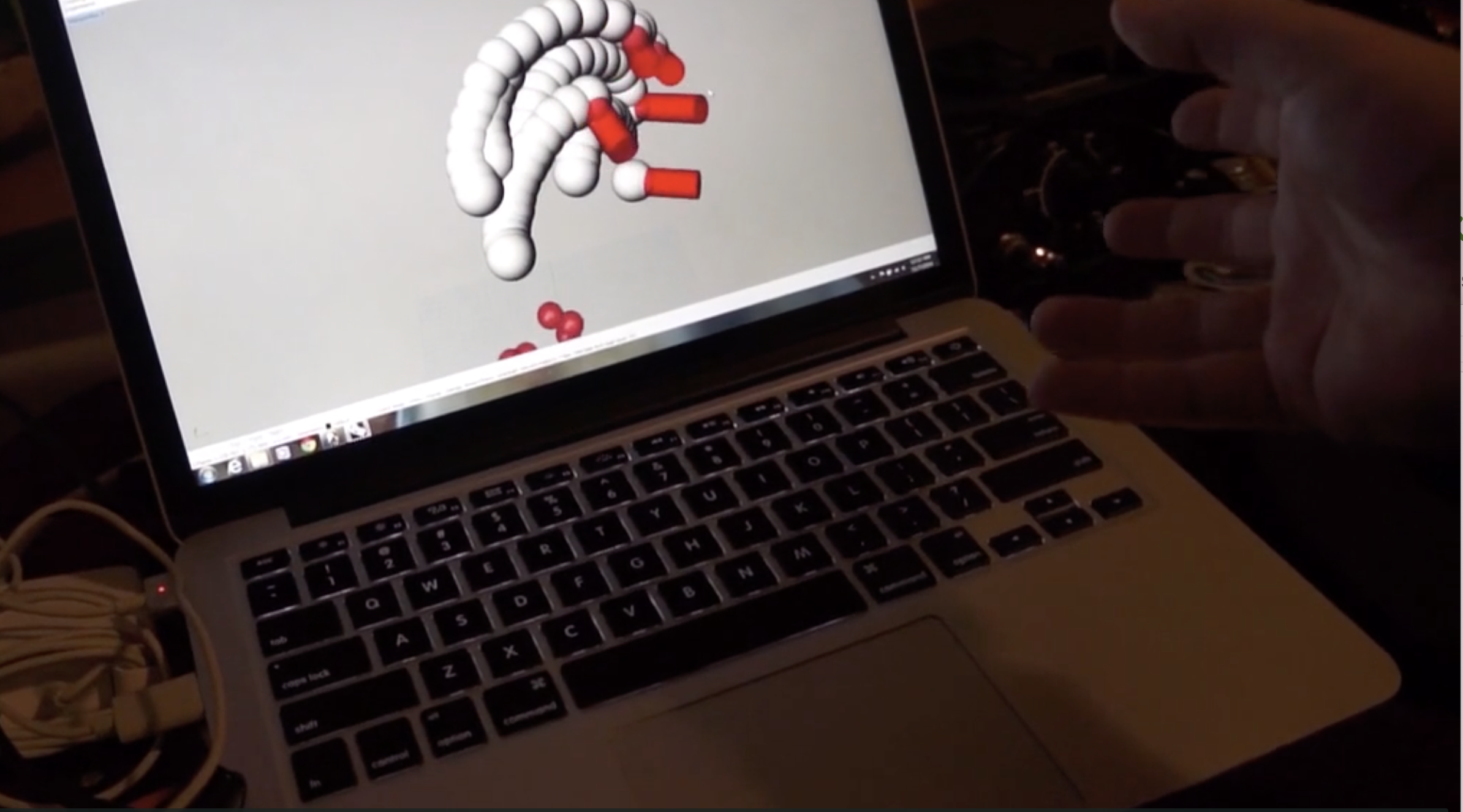

I researched and developed a flexible 3D printable foam structure that can be formed to a person’s body. The structure allows any part of the chair to be customized for shape, density and softness which can be used to affect the way a person sits in a chair potentially correcting posture and ergonomics. In the design development of this structure, I strived to produce a open 3d printable, foam structure that would produce a structurally sound product with very little vertical elements to reduce material consumption, as well as be printable with little to no additional support structures.

Manufacturing processes are very important to think about while designing, especially when it comes to the cost and time. The benefits of additive manufacturing is that each product or “thing” produced can have slightly different elements in each “thing”. Unlike mass production that is based on repetitive making of a single “thing”. For example, an injection molded chair needs to have a mold produced that cost thousands of dollars but can be used millions of times as long as the chair form is not changed. But if you want to change something as simple as change in the diameter of the legs, you would have to produce a new mold, making it very costly to change elements without making it modular. For example, Doctor Scholl’s Custom Fit Orthotics are based on fourteen different “foot types” that match your foot giving you a custom fit. This is a way to make something custom without manufacturing a different form for each person. Places where custom forms are used are in products like Invisalign Braces, custom hearing aids, and true custom orthotics.

Research

Overall my project is designed to build a system that allows me to produce custom made, individually specific furniture that could be used to make a more comfortable chair or become a method to correct ergonomics, posture, or back pain mediation. I am not necessarily making it for one or all of the above but I do plan on collaborating with outside medical professionals. Dr. Joe Ferrantelli from PostureScreen Mobile, a chiropractor who developed an application that uses photos to identify and document posture issues is now using the structure scanner to do 3d documentation of patients. He said, “I don’t know of any studies that could prove this to be relevant but intuitively I would say, ‘Yes!’,” .

This then could be taken further to a study of how sitting in a correct posture could be made possible by a chair that is made directly for your body. Dr. Joe, explained that in order to adjust the spine the soft tissue has to be held in a specific location for at least fifteen minutes. Because people working in an office sit in chairs four to eight hours a day, this is feasible. It all depends on how that form actually affects you, for example lumbar support can be added specifically in the area that is needed. All these elements are hypothetical if they actually work or not, but what I have produced is an ability to generate these forms. Because of this, I can test how well it will work. Before now, I did mostly exploration and research on how it can be produced and whether this is relevant or not. Now that I have a proven way of constructing these forms, I can go to the next step of how to test this.

Conclusion

Why am I so interested in chairs? Chairs are one of the most complicated pieces of furniture to design, because we do not just touch them with our hands but with our whole bodies, so there are many factors to be considered in the design. In Theodore Roethke’s book, The Chair. he writes “A funny thing about a Chair: You hardly ever think it’s there”. This is very true; people take them for granted but should that be changed?

Stats/Info

Degree: Parsons New School for Design

Program: MFA Design & Technology

Faculty Fall: Scott Pobiner & Louisa Campbell

Faculty Spring: Kate Sicchio & Edward Jefferson

Year: 2015-2016

Medium/Materials

Digtial, Coding

Interaction Design

Furniture Design

Tools/Skills Used

Coding

Rhino & Grasshopper

Sensor Scanner

3d scanning

Digital Fabercation

3d printing